Mechanical-welding services steel structures

Within the framework of its activities the company PPH Energo-Silesia Sp. z o. o. provides services in the mechanical sector based on entrusted documentation and our own documentation.

We perform locksmith, welding and machining works.

|

|

|

|

|

STEEL STRUCTURES:

- sheet metal cutting on a plasma scraper with CNC control, working table with dimensions of 3000×6000 mm, maximum plasma cutting thickness – 50mm, maximum gas cutting thickness 200mm, the possibility of 3D cutting in pipes;

- bending on an edge press with CNC control, maximum bending thickness of 3000mm, maximum bending thickness 12mm;

- mechanical cleaning of metal surfaces with steel shot in a professional shot-blasting booth,, (LxHxW) 9.3m / 3.9m / 2.9m, entrance gate 3.6 / 2.7m, maximum load of the grating 1.5 t/m2;

- lacquering the elements in a professional paint spray booth, (LxWxH) 9.6m / 3.9m / 2.9m, entrance gate 3.6 / 2.7m;

- cutting pipes, rods and sections on a saw blade with a hydraulic feeder with a maximum dimension of 600x600mm;

- assembly and welding works using MAG-MIG and TIG methods..

We have a rich and modern machinery park as well as experienced staff with the necessary qualifications. We offer comprehensive production and the individual performance of particular operations.

We provide services on an ongoing basis in the scope of:

- production of various types of oil tanks for hydraulic equipment;

- production, renovation and modernization of elements of large and medium power transformers vats (vents, beams, etc.)

- steel constructions for the power industry such as electric power poles, power station components, trusses, etc.

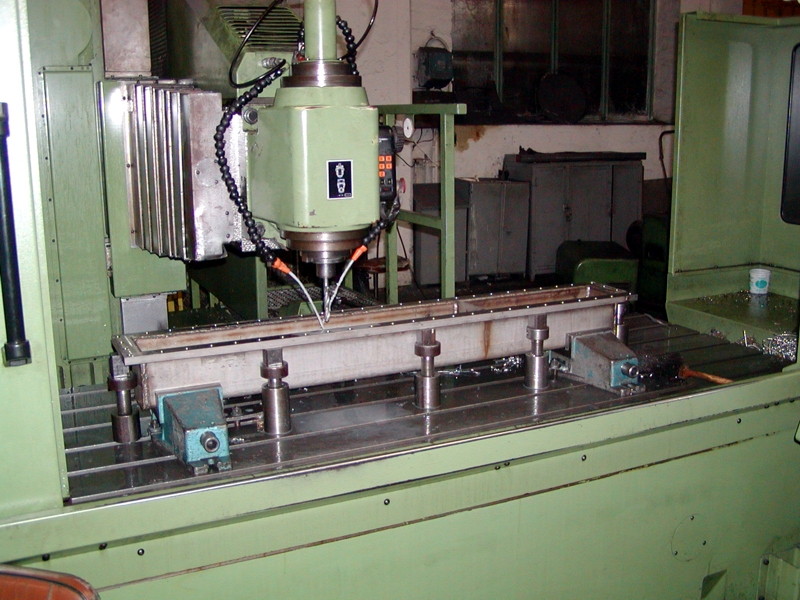

MACHINING:

turning on CNC machine tools: max diameter 450 mm, max. diameter of workpiece 60 mm, length of workpiece 650 mm;;

turning on conventional lathes: max. diameter 1600 mm, max. length 5000 mm;

milling on CNC machine tools: max. gantry travels (X, Y, Z) 8000x1200x800, possibility of using the fourth axis, i.e. horizontal head indexed every 1 degree;

milling on CNC machine tools: maximum travels (X, Y, Z) 1480x630x630, we have a four-spindle machine tool, there is the possibility of simultaneous drilling, e.g. boring of flanges, etc.;

milling on conventional machine tools: max. travels (X, Y, Z) 3150x2500x1200, rotary table 2000 × 2000, carrying capacity 20 Mg;

planing: max. travels (X, Y, Z) 6000x1750x700

In addition, we conduct machining on radial and column drills as well as grinding of the planes of shafts and holes.