Control system

SAFE AND RELIABLE CONTROL SYSTEM

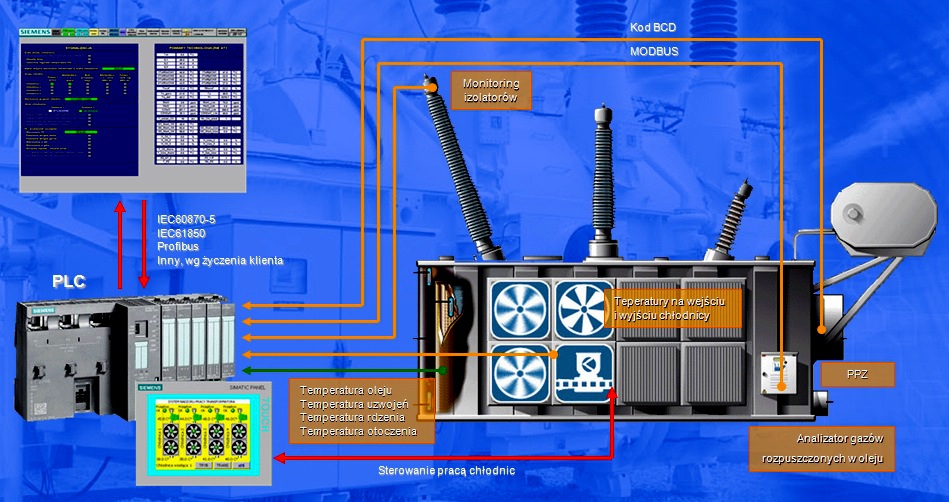

We offer many variants of transformer cooling control systems. However, they have some common features. The most important ones include the fact that the SIEMENS or WAGO PLC controllers are used in control cabinets. The use of a suitable type of controller depends on the requirements set to a specific application and its degree of advancement.

PLC controllers perfectly integrate with other transformer accessories, also with online monitoring systems. Digital data transmission is carried out by communication protocols: IEC60870-5, IEC61850 and Profibus. Communication can be conducted through electrical, fibre optic, or GSM. Additional messages can be sent using text messages and email.

DIAGNOSTICS SECURING THE PROCESS

Use of the controller allows performing many additional tasks not directly related to the control of the cooling process. All functions can be performed online with the provision of two-way communication.

Here are some examples of possible tasks:

- cooperation with gas analysers dissolved in oil,

- diagnosing the performance of individual modules, detecting a drop in thermal efficiency,

- monitoring of the on-load switch of transformer taps,

- monitoring of insulators,

- checking the condition of the remaining equipment built on the transformer.

OPTIMIZATION OF ROTATIONAL SPEED OF FANS

The control system can choose the capacity of the fans so as to ensure optimum cooling at the lowest permissible speed.

Changing the rotational speed can be done in different ways:

- Multi-speed motors.

- Voltage regulation.

- Frequency adjustment.

The most effective way is to use inverters. For safety purposes and the reliability of the cooling system operation, the system can diagnose the problem and disconnect the inverter by switching to conventional operation (we prefer operation without division into cooling groups).

OPTIMAL, COMPREHENSIVE SOLUTIONS

- Application of PLC control devices allows minimizing the number of components in the control cabinet, which increases the reliability of the entire system.

- When assembling cabinets we use the equipment of reputable companies.

- Production is conducted based on our own or an entrusted design. The cabinet configuration can be arbitrary (free-standing or hanging cabinets).

- Cabinets are made with the IP degree of protection, material type (stainless, galvanized steel, aluminium) as it is required by the conditions.

- Cabinets can be equipped with temperature and humidity control as well as heating and air conditioning systems.

Our offer is comprehensive. It relates to the design, performance and commissioning of the whole control system for transformer cooling as well as its servicing.

We offer a complete cooling system for our customers, together with oil-air coolers produced by our company.

PJ