Modernization of transformer cooling systems with coolers

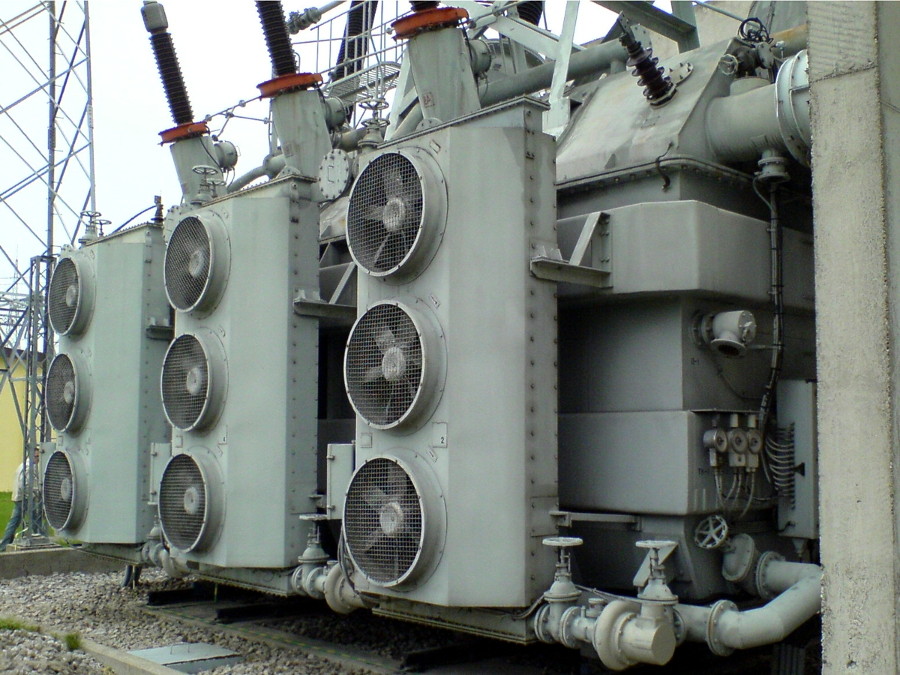

The problem of cooling systems leakage on network transformers also does not evade the transformers cooled by fan coolers. The cooling systems for high power transformers manufactured in the 1970s and 1980s are more frequently subject to unsealing. In most cases, they are very elaborate systems, with a large number of coolers and, connected with such, a large number of potential places in which leaks occur or may occur (a large number of flange connections, pipes in coolers are connected to the sieve bottoms by rolling).

|

|

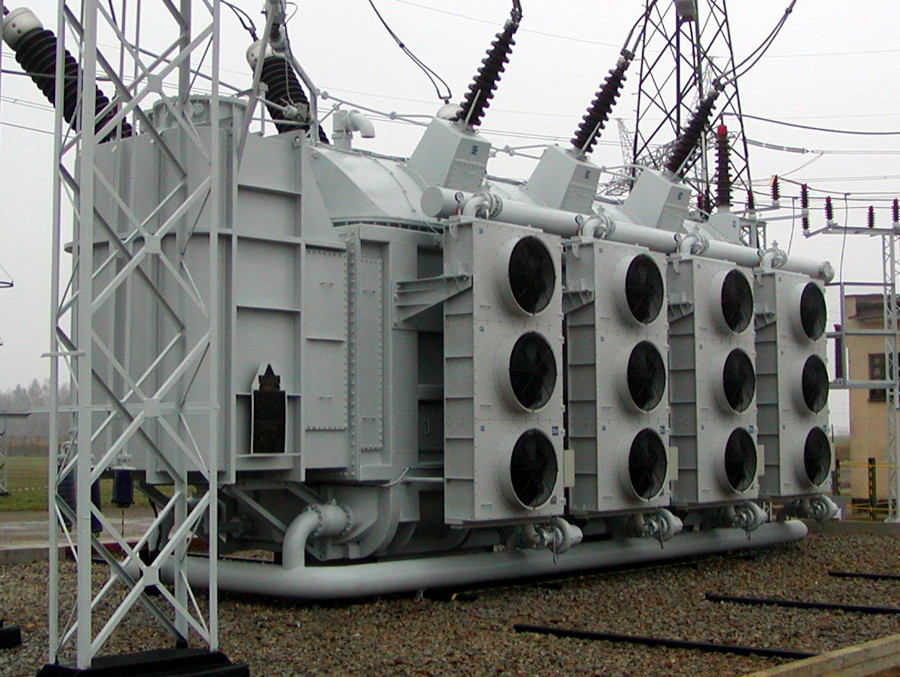

Within the framework of cooling systems modernization based on fan coolers, our company conducts repeated heat calculations, taking into account the current transformer’s operating parameters, its degree of wear, etc. The best results are achieved when the coolers are built on the basis of monolithic aluminium pipes ribbed on both sides. However, there is a possibility of making coolers based on bimetal pipes with aluminium ribs where the base pipe is made of stainless steel, less often of black steel and brass. In addition, new cooling systems can be equipped with state-of-the-art intelligent control systems based on SIEMENS intelligent controllers.

|

|